GBC Supports Investment Casting

August 2, 2024

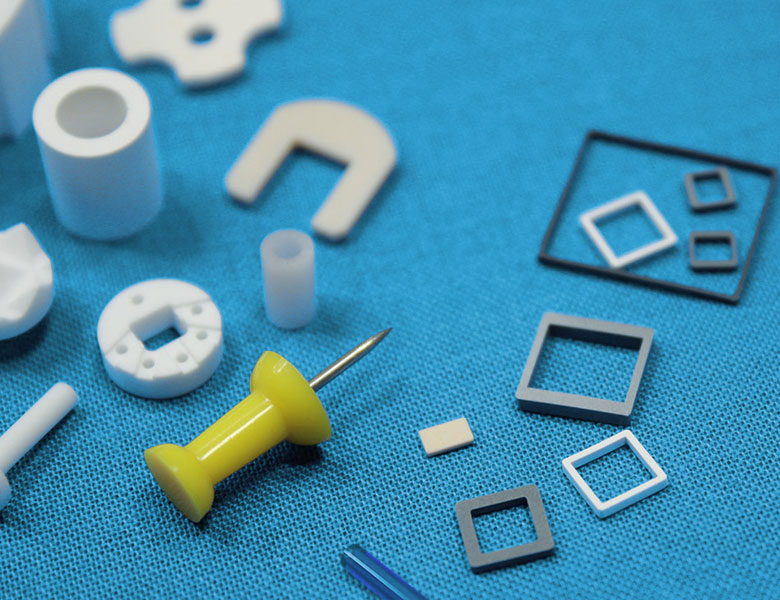

Exploring the World of Precision Ceramics With GBC Advanced Materials

December 12, 2024Glass Preforms / Drawn Glass / Pressed Glass / Hermetic Seals / Hermetic Connectors / Feedthroughs

Glass preforms, drawn glass, and pressed glass each serve unique roles in manufacturing and technology. A glass preform is a precision-shaped material, drawn glass is made by pulling molten glass into tubes, and pressed glass is formed from glass powders. These components come in diverse geometries, tailored to meet specific industry requirements and performance standards.

This article explores the importance and benefits of these types of glass from GBC Advanced Materials, highlighting their precision, durability, and versatility.

Glass Preforms

Glass preforms are special-shaped pieces of glass used in various industrial applications, including fiber optics and telecommunications, due to their durability. They enhance performance and reliability in high-tech environments, which makes them indispensable in multiple applications.

These uses highlight the versatility and importance of glass preforms in various industries, contributing to technological advancements and improving the quality of products and services:

Aerospace

A glass preform is integral to aerospace applications, particularly for high-temperature electrical insulators, hermetic assemblies, hermetic packages, and microwave device packages. These components benefit from the excellent thermal and electrical insulation properties of glass, ensuring reliability in demanding environments.

Medical Equipment

Precision glass components are crucial in medical equipment as they enhance the accuracy and reliability of sensors and analytical instruments. Their use in diagnostics and treatment devices underscores their importance in medical technology.

Semiconductors

Glass preforms are vital in semiconductor equipment, especially for insulating components and circuits in electronic packages. They provide the necessary thermal and electrical insulation required for high-performance semiconductor devices.

Communications

This type of glass is indispensable in communication devices, where it functions as a key component in gas laser tubes and high-voltage insulators. Its role in enhancing signal transmission is vital for the optimal performance of communication technologies.

Drawn Glass

Drawn glass is created by extruding molten glass through a die — a process primarily used for producing glass tubing. This cost-effective method ensures high-quality glass with consistent wall thickness, making it ideal for modern electronics applications where precision and durability are essential.

The following are the applications of drawn glass in various industries:

Medical Devices

Drawn glass is extensively used in medical equipment for its precision and electrical properties. Extruded glass is utilized in medical sensors, diagnostic instruments, and imaging devices.

Aerospace

This type of glass is vital for creating durable and lightweight components in the aerospace industry. It is utilized in the manufacturing of instrumentation and high-temperature insulators.

Semiconductor Manufacturing

Drawn glass is crucial in semiconductor equipment due to its thermal stability and electrical insulation properties. It produces electrical packages, insulators, and other critical semiconductor components.

Electronics

The electronics industry benefits from drawn glass in various applications. It is used for computer peripherals and communication devices.

Pressed Glass

Pressed glass is made by pressing powdered glass using punches and dies, enabling the production of intricate and consistent shapes like multi hole insulators and preforms. This method is essential for creating detailed, uniform glass items for functional purposes.

The following are the applications of pressed glass components in industry, leveraging its versatility and strength:

Automotive

Pressed glass is used to manufacture various components that require safety and functionality in the automotive industry.

Hermetic Seals

Hermetic seals are airtight seals incorporating glass to protect sensitive components from environmental factors like moisture, dust, and gases. The glass used in these seals is crucial for ensuring the seal’s impermeability and durability, especially in electronics, aerospace, and medical devices. The term “hermetic” emphasizes the complete airtightness and protection of the glass-to-metal bond within these seals.

Hermetic Connectors

Hermetic connectors are specialized electrical connectors designed to maintain a hermetic seal using glass. This unique design prevents the entry of moisture, gases, and contaminants, ensuring the integrity of electrical connections even in the most challenging environments. The glass component is crucial for achieving a reliable seal, which makes these connectors ideal for highly reliable applications.

Feedthroughs

Feedthroughs are components that allow electrical or optical signals to pass through a barrier while maintaining a hermetic seal. Using glass guarantees that no contaminants enter the protected space, making these components ideal for applications in vacuum systems, where preserving a controlled environment is vital.

Choose GBC Advanced Materials for High-Precision Glass Components For Hermetic Applications!

GBC Advanced Materials offers superior glass preforms, drawn glass, and pressed glass for various industries, ensuring high precision and durability in every component. We supply top-notch manufacturers of hermetic seals, hermetic connectors, and feedthroughs, which deliver solutions that protect sensitive components from environmental factors. Our commitment to exceptional customer service, continuous improvement, and timely delivery ensures that your projects meet the highest standards.

Contact us or request a quote today for advanced ceramics and hermetic solutions!