Glass Preforms / Drawn Glass / Pressed Glass / Hermetic Seals / Hermetic Connectors / Feedthroughs

December 6, 2024

GBC Advanced Materials Chooses XJet Ceramic Solution to Scale-up Production

December 18, 2024Exploring the World of Precision Ceramics With GBC Advanced Materials

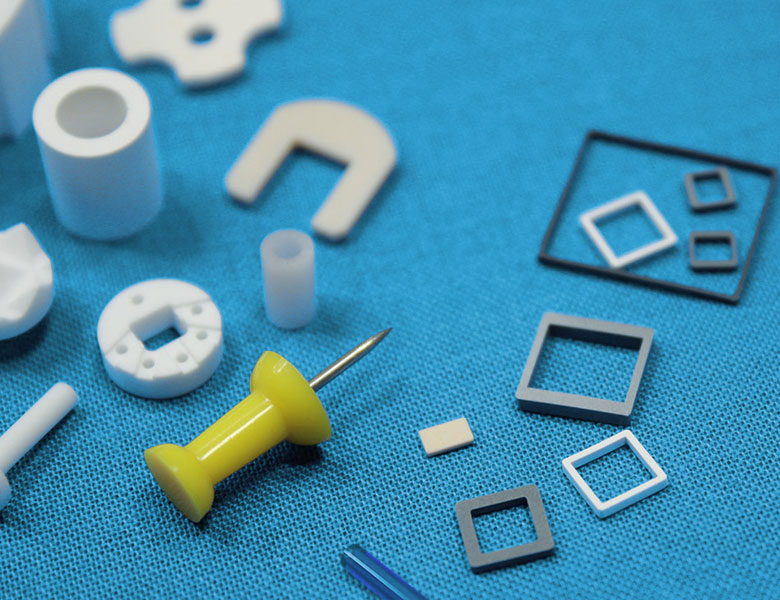

Advanced or precision ceramics are crafted from high-purity inorganic compounds. They feature precise dimensions and exceptional properties, such as strength and corrosion resistance after high-temperature sintering. Their unique structures and compositions have varying functionalities crucial in the electronics and biotechnology industries.

Key Aspects of Precision Ceramics

Here are the essential elements of advanced ceramics that guarantee a wide array of premium products:

Alumina Ceramics

Alumina ceramics, with purity levels of 85% to 99.8%, are valued for their strength and durability in electronic, wear, mechanical, and high temperature applications. In electronics, they offer superior electrical and thermal insulation, while their hardness and wear resistance make them ideal for wear applications. Additionally, their ability to withstand extreme temperatures makes them indispensable for thermal applications such as industrial heaters and aerospace applications.

Glass Sealing Preforms

Glass sealing preforms are integral components in many industries, offering vital solutions for achieving dependable seals in electronic, mechanical, and thermal applications. The preforms come in diverse compositions and thermal expansion ranges, meticulously designed to match specific application requirements. Rigorous batch controls ensure uniformity in composition and thermal properties, guaranteeing reliability and consistency in sealing operations.

Glass sealing preforms are crucial for creating hermetic seals in electronic packages, medical devices, and sensitive equipment. Their versatility and reliability make them indispensable in sealing technology, driving innovation and ensuring optimal performance in critical processes across industries. GBC makes glass preforms for rectangular / square flat packs, glass to metal seals, and hermetic packages / hermetic assemblies. These products are essential for the aerospace and medical arenas.

GBC Advanced Materials’ Services and Capabilities

The following are the services and capabilities provided by GBC Advanced Materials:

Forming

Our forming capabilities encompass the following:

- Mechanical Pressing: utilizes steel or carbide tooling to create net or near-net shapes, ensuring precision, uniformity and high throughput.

- (CIP) Cold Isostatic Pressing: produces high integrity billets and enables the production of large parts over a foot in size.

- Hot Isostatic Pressing (HIP): enhances material properties through high-pressure and heat treatment.

- Extrusion: a versatile process that involves forcing highly viscous ceramic mixtures through shaped dies to create rods and tubes with intricate geometries. This method finds applications in medical, aerospace, and electronic industries, where precise shapes and dimensions are crucial for component performance. Ceramic extrusion enables the production of parts up to 36in long.

Green Machining

Green machining involves machining ceramic components while unfired, reducing cost and lead time. It employs CNC machining centers with custom improvements to work efficiently with ceramics. Steel and carbide tools along with abrasive wheels ensure efficient machining.

Sintering

Sintering strengthens ceramic components by heating formed materials & creating solid bonds between particles for enhanced performance. GBC Advanced Materials’ process ensures optimal material properties, removing pressing lubricants and binders.

Precision Grinding

GBC’s precision grinding services encompass CNC and conventional hard grinding, catering to the precise dimensional requirements of ceramic components. Considerations such as speeds, feeds, cutting abrasives, and coolant usage are meticulously managed to minimize heat generation and ensure the integrity of the final product.

Industries Leveraging Precision Ceramics

Listed below are the applications of precision ceramics across industries:

Medical

Precision ceramics are used in dental implants, surgical instruments, prosthetics, medical imaging devices, and other healthcare tools. Their biocompatibility, corrosion resistance, and strength-to-weight ratio enhance equipment safety, durability, and effectiveness, improving patient outcomes and healthcare delivery.

Aerospace

In aerospace applications, precision ceramics are vital for reliability and performance. They are used in engines, turbines, and structures. Their ability to withstand extreme conditions enhances safety and efficiency, from lightweight components improving fuel efficiency to thermal protection systems ensuring safety during re-entry.

Electronics

Precision ceramics drive innovation and performance in electronics components like semiconductors, circuit boards, sensors, and packaging. These materials provide excellent electrical insulation, high thermal insulation, and strong resistance to corrosion and wear.

Elevate Your Projects With GBC Advanced Materials’ Precision Ceramics

GBC Advanced Materials is your premier destination for precision ceramics and glass products! With our expertise and 50,000-square-foot cutting-edge facility in Latrobe, PA, we specialize in crafting high-quality components from miniature to large-scale.

Contact Us today to elevate your projects with us!