Advanced Ceramics in Instrumentation and Scientific Equipment

January 24, 2022

GBC Supports Investment Casting

August 2, 2024The Future of Advanced Ceramic Manufacturing at GBC Advanced Materials

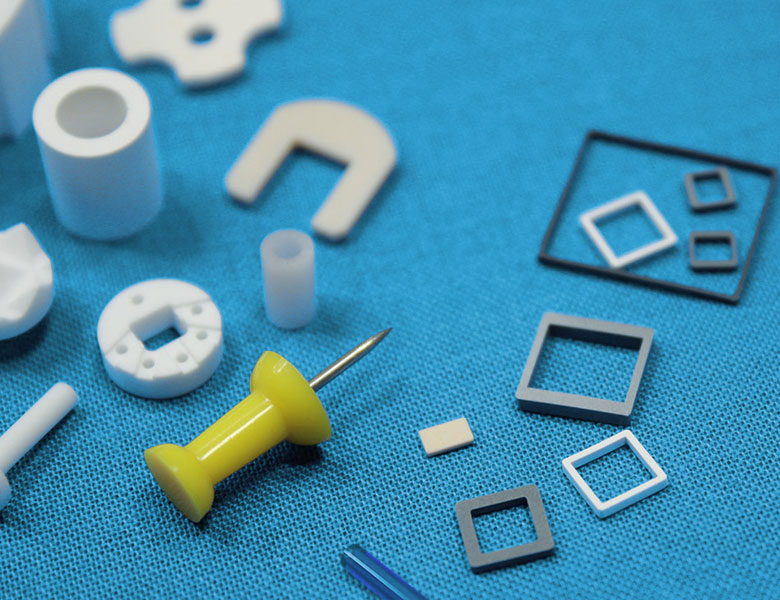

GBC Advanced Materials leads ceramic manufacturing with expertise in alumina ceramics from 85% to 99.8% purity. Our precise material control ensures consistency in electronics, wear resistance, mechanics, and thermal management. We utilize advanced presses and craft intricate components with tight tolerances, including miniature alumina tubes for medical devices.

This article explores how GBC Advanced Materials is reshaping advanced ceramic manufacturing — from innovative technologies to streamlined processes.

A History of Innovation

The following are the advancements facilitated by GBC Advanced Materials and their impact on ceramic production:

Enhanced Precision and Production Efficiency

GBC Advanced Materials’ technological advancements include innovative ceramic production, ensuring unmatched precision and efficiency. We have achieved closer near-net dimensions through ISO pressing, dry pressing and green machining practices, which reduces the need for extensive post-processing. This also enhances the production efficiency and quality of each ceramic component. Our dry pressing technology increases output and reduces costs compared to laser processing and diamond grinding.

Expanded Design Possibilities and Material Capabilities

Our innovative capabilities present a range of design possibilities for ceramic users. Using extrusion techniques, we create ceramic parts of varied shapes and sizes. Expertise in polishing and lapping ensures dimensionally accurate components with superior performance and aesthetics.

Improved Material Durability and Performance

Through advanced research and development, we have formulated ceramic materials with improved mechanical properties, thermal stability, and chemical resistance. This enables the production of parts capable of withstanding harsh operating conditions.

Process Improvements

Here are the ways GBC Advanced Materials is driving continuous growth, increased efficiency, and process improvement:

Redefining Traditional Processes

We have pursued an innovative approach by redefining conventional ceramic manufacturing processes. Our discernment of areas for enhancement through meticulous analysis and creative approaches has led to the execution of strategic changes to augment production efficiency and sustainability.

Streamlining Production Workflows

A key focus of our process improvements has been streamlining production workflows. By identifying and eliminating inefficiencies, we have significantly reduced lead times and enhanced overall productivity. Our optimized operations ensure that each manufacturing process step is structured for maximum efficiency.

Maximizing Resource Utilization

Efficient resource utilization is paramount to sustainable manufacturing practices. At GBC Advanced Materials, we have implemented advanced techniques such as ISO pressing and green machining to maximize the use of available resources. This minimizes waste and contributes to a more environmentally friendly production process.

Enhancing Material Quality

Quality standards are indispensable in advanced ceramic manufacturing. Therefore, we prioritize enhancing material quality throughout our production processes. Our strict quality control measures and continuous improvement initiatives ensure that each ceramic component meets the highest performance and reliability benchmarks.

Advancement Prospects

Listed below are the aspects of GBC Advanced Materials’ role in advancing ceramic manufacturing, along with the impact of these advancements on industry standards:

Additive Manufacturing

One of the most exciting frontiers in ceramic manufacturing is additive manufacturing or 3D printing. Our expertise in this field will enable intricate designs and complex geometries previously deemed impossible. This allows us to produce customized ceramic components with unmatched precision and efficiency.

Advanced Material Formulations

Our company’s dedication to research and development enables the creation of advanced material formulations that push the boundaries of ceramic performance. Whether they enhance strength, durability, or thermal conductivity, our innovations facilitate new applications across a wide range of industries.

Innovative Manufacturing Techniques

At GBC Advanced Materials, we are unwavering in our commitment to improving manufacturing techniques to streamline production processes and cut costs. From advanced dry press capabilities to precision machining, we leverage cutting-edge technology to optimize every step of the manufacturing process.

Partner With GBC Advanced Materials for Innovative Ceramic Solutions!

At GBC Advanced Materials, we are dedicated to advancing ceramic manufacturing. Our focus on technological breakthroughs and process improvements ensures industry-leading innovation. Partner with us for precise solutions tailored to your needs, backed by our commitment to quality and efficiency!

Contact us to learn more or request a quote today.