Services & Capabilities

Precision Ceramics and Glass

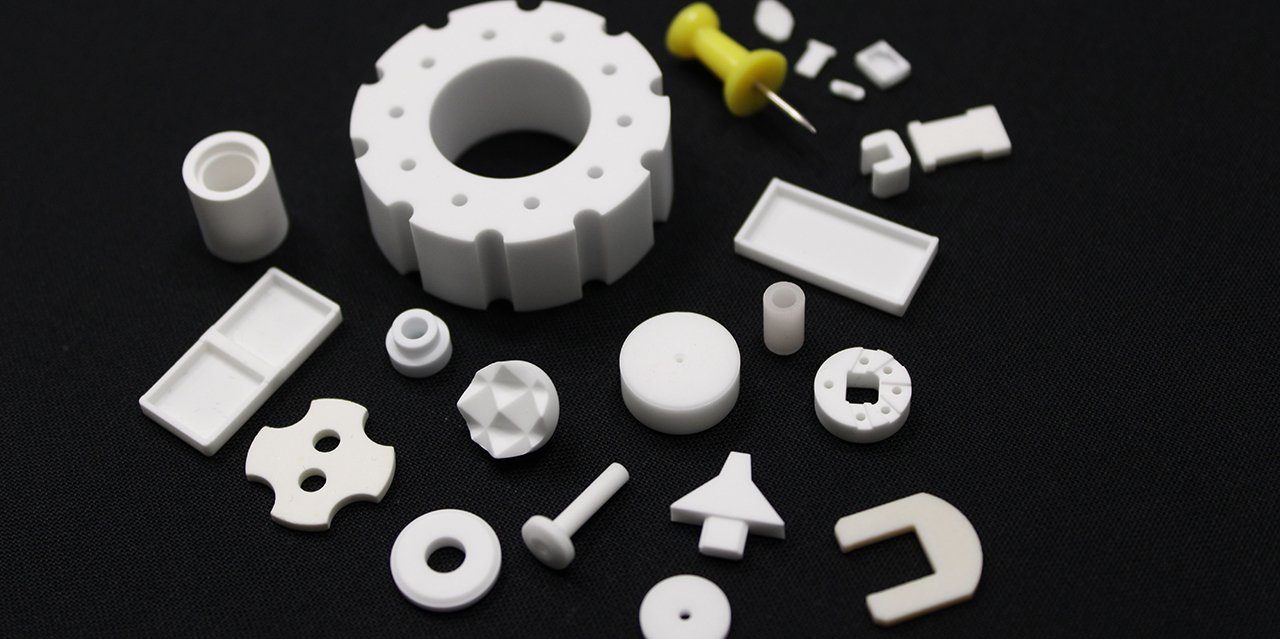

At GBC Advanced Materials, we are a precision manufacturer of glass and ceramic components from miniature to 1 cubic foot and larger.Our Materials

ALUMINA CERAMICS

Alumina ceramics, available in purity levels from 85 to 99.8%, are used in electronic, wear, mechanical, and thermal applications. Precise material batch control (from milling through spray drying) and powder sizing assures reproducibility from order to order and through the life of long production runs. Parts are produced using presses that range in size from 1 to 40 tons and complex motion capabilities allow tight tolerance controls as well as multi- level and multi-hole geometric configurations.

GBC's small, pressed alumina tubes and rings are ideal for use in instrumentation and electronic devices, especially sub-miniature electronic devices, many of which are used in the medical industry. These tiny ceramic parts offer ID as small as 0.007". Minimum wall thickness is 0.010" and minimum length is 0.008". The maximum length-to-wall thickness ratio is 8:1. multi-cavity tooling enable fast, high-volume production, at a low cost. The 96% alumina composition is an easily metallizable ceramic.

Al2O3 85% / 92% / 96% / 97.5% / 98% / 99.5% / 99.8%

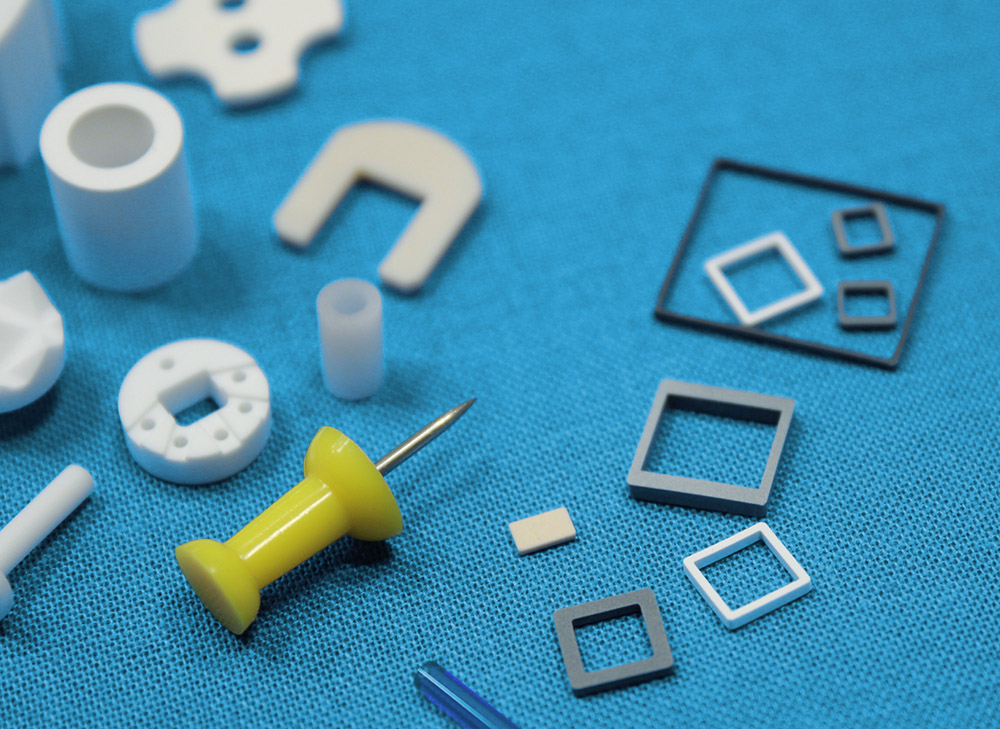

GLASS SEALING PREFORMS

Glass Sealing Preforms are available from GBC Advanced Materials in a variety of compositions and thermal expansion ranges. Stringent batch controls provide the highest degree of dependability. The preformed frames, rings and solids introduce a finite amount of sealing glass, which can be shaker loaded into sealing fixtures. Research and development is continuing to provide a wide range of expansion coefficients in low temperature sealing glasses.

Low Expansion Glass

- GBC 505 - Corning C7070

Matched Kovar Type

- GBC645 - Fusite K

- GBC691 - 7052 Equivalent

- GBC555 - Corning C7052

- GBC593

Compression Seals

- GBC365 - 9013 Equivalent

- GBC614 - 9013 Equivalent

- GBC661 - Fusite T

Alumina Ceramics: Available in purity levels from 85-99.8%. Used in electronic, wear, mechanical, and thermal applications.

Glass Sealing Preforms: Many glass compositions with Low Expansion, Kovar Matched, and Compression seal glasses.

Ceramics

- Aluminum Oxide (Al2O3)

- Zirconium Oxide (ZrO2)

- Macor

- Steatite L3 and L5

- Mullite & Cordierite

- Fused Silica

Glass

- Mechanically Pressed & Drawn Glasses

- ULE / Zerodure (low CTE glasses)

- BK7 (optical glass)

ISO 9001:2015 - Certificate of Registration

ITAR Certification Coming Soon

Our Capabilities

ISO-PRESSING

Mechanical Pressing utilizes steel or carbide tooling that creates a "net or near net" shape. By filling the tool with powder and applying uniaxial pressures to compress the powder.

Cold Isostatic Pressing is a method of compacting powdered materials into a solid homogeneous mass before machining or sintering. Sometimes referred to as hydrostatic pressing, it is a very simple process capable of producing high-integrity billets or preforms that exhibit little distortion or cracking when fired.

Hot Isostatic Pressing (HIP). This process is available through one of our trusted vendors.

Benefits of ISO Pressing

- Uniform Strength in all directions: The pressure used to compact the powder is applied equally in all directions.

- Uniform Density: The resulting compacted piece will have uniform shrinkage during sintering with little or no warpage.

- Shape Flexibility: Isostatic pressing makes it practical to produce shapes and dimensions that are difficult or impossible to produce by other methods.

- Component Size: Wide range of component sizes can be made.

- Larger Parts: Part sizes are limited only by the size of the isostatic pressure chamber.

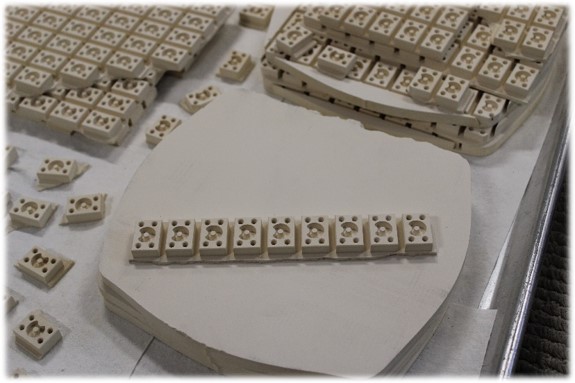

GREEN MACHINING

The machining of a ceramic in the unfired state is called Green Machining. This is done in ceramics whenever possible as a method of attaining closer near net dimensions thus reducing the amount of post fired/diamond grinding costs resulting in shorter lead-times. Typical as-fired tolerances are +/-.005” or +/-1% of a dimension whichever is greater.

The CNC machining centers used are very similar to those found in many machine shops with custom improvements for working in soft ceramics. Due to the extremely abrasive nature of ceramics, they can only be green machined efficiently using carbide and PCD tools and abrasive wheels. The softer nature of green ceramics dictates a less aggressive approach to cutting and work holding methods.

SINTERING

Sintering is a heat treatment applied to a powder compact in order to impart strength, integrity and densification. The temperature used for sintering is below the melting point of the major constituent of the ceramic powder material.

After compaction, neighboring powder particles are held together by cold welds, which give the compact sufficient “green strength” to be handled and green machined. At sintering temperature, diffusion processes cause necks to form and grow at these contact points.

There are two necessary precursors before this “solid state sintering” mechanism can take place:

- Removal of the pressing lubricant by evaporation and burning of the vapors (organic binders)

- Reduction of the surface oxides from the powder particles in the compact.

Control Shrink

Control of temperature is very important to the sintering process, since grain-boundary diffusion and volume diffusion rely heavily upon temperature, the size and distribution of particles of the material, the materials composition, and often the sintering environment or atmosphere.

Solid State Sintering is associated with a remarkable shrinkage of the material because glass phases flow once their transition temperature is reached and start consolidating the powdery structure and considerably reducing the porosity of the material.

PRECISION HARD GRIND

CNC & Conventional and Hard Grinding is the removal of material from a part either to reduce it to a suitable size, to remove large irregularities from the surface, to induce a certain surface finish condition and/or to hold a dimensional tolerance tighter than what can be held when firing ceramics that shrink between 15% and 28% during sintering.

Grinding is a process that needs to consider speeds, feeds, cutting abrasives and the coolants used to minimize amount of heat being generated so as not to cause deep subsurface damage in ceramic and glass materials.

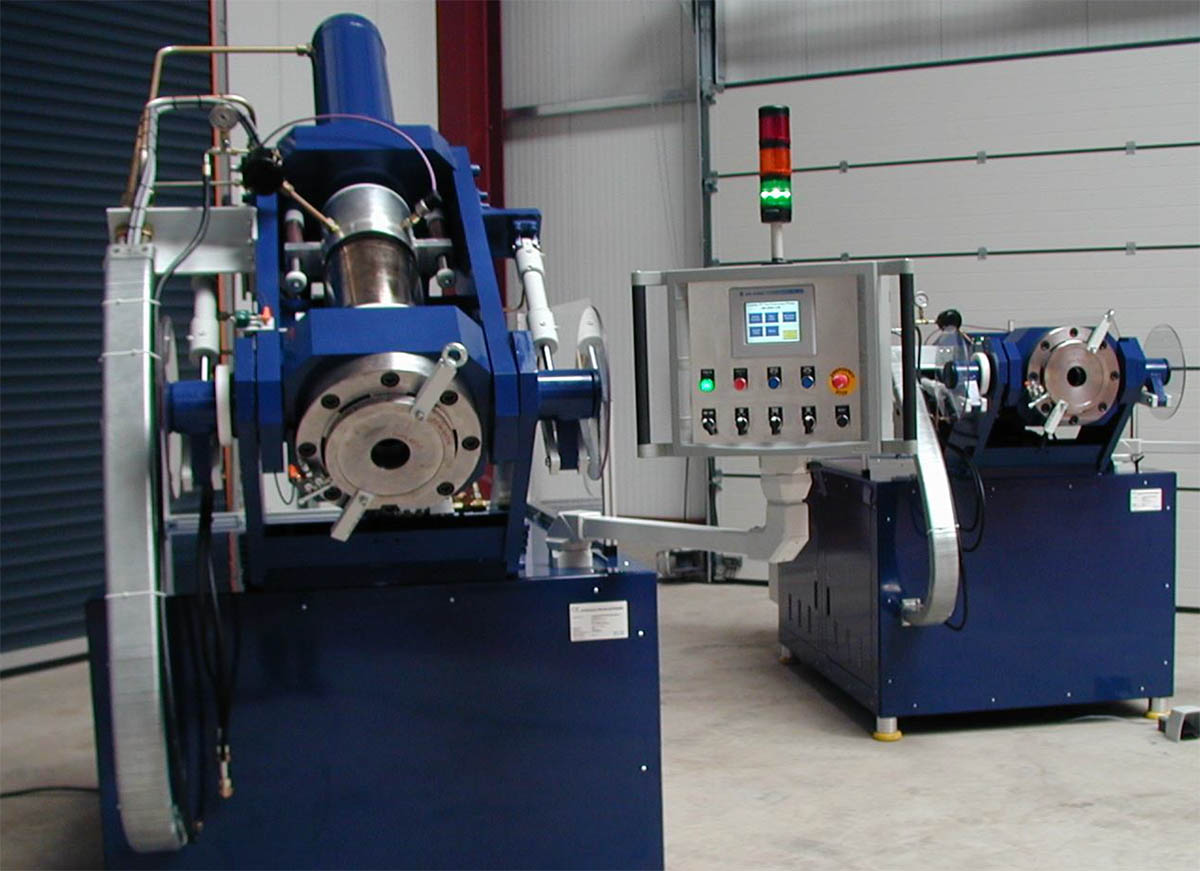

EXTRUSION

In the extrusion process, a highly viscous plastic mix of ceramic powder with additives is forced through a shaped die using high force. This is similar to squeezing a mixture with the consistency of potters clay through a shaped tube like a cake decorator squeezes frosting from a bag.

Our state-of-the-art vertical hydraulic piston extruder makes rods and tubes in a variety of sizes, shapes, and tolerances. This method allows for rods from .025" to .400" solid, single-hole or multi-hole - with significantly longer lengths than you can get with a pressing process.

We are producing rods in high purity Alumina and Steatite, widely used in medical, aerospace and electronic applications. The extrusion process delivers a high volume of intricate parts in a short lead time that is extremely cost-effective compared to components produced by traditional machining.