The Future of Advanced Ceramic Manufacturing at GBC Advanced Materials

August 2, 2024

Glass Preforms / Drawn Glass / Pressed Glass / Hermetic Seals / Hermetic Connectors / Feedthroughs

December 6, 2024GBC Supports Investment Casting

GBC Advanced Materials’ journey traces back to its roots in glass production, swiftly adding ceramics in response to industry demands. Almost 20 years ago, acknowledging the increasing demands of the investment casting industry, we introduced alumina rods and tubes tailored for casting applications.

This article delves into GBC Advanced Materials’ innovative product offerings tailored to address the requirements of the investment casting industry. We will also discuss our manufacturing capabilities to support investment casting, highlighting our expertise in production excellence. As a privately held firm we are nimble enough to respond quickly to new requests.

Our Products

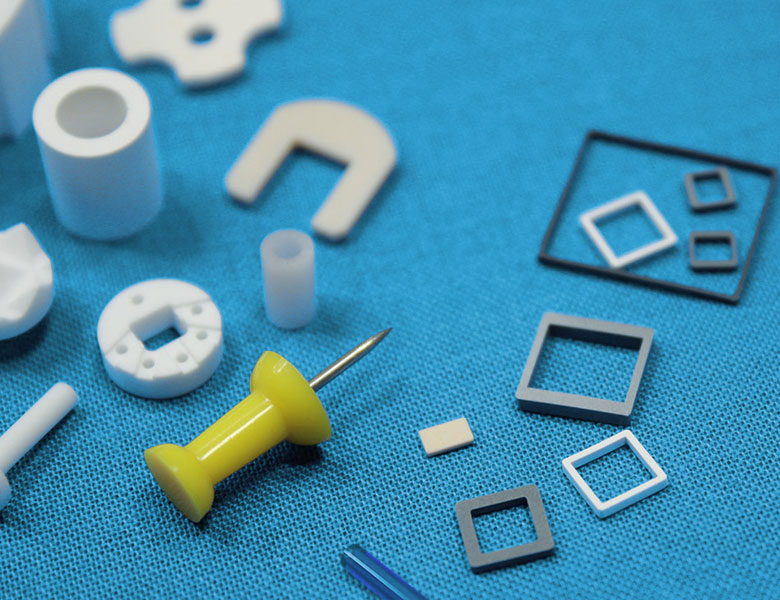

Here are the innovative product offerings of GBC Advanced Materials, catering to the diverse needs of the investment casting industry:

Alumina Rods

Available in various grades with purities up to 99.8%, alumina rods enable us to realize complex shapes within casting processes. These rods reinforce leachable cores, ensuring structural integrity and supporting intricate designs. We have the capability to cut notches to a client’s spec.

Alumina Tubes

We offer tailored alumina tubes for investment casting applications to complement our alumina rods. These tubes serve diverse needs within the casting process, providing additional support and structural reinforcement.

Fused Silica Rods

Our fused silica rods are crafted with precision and designed to meet the stringent demands of investment casting. Offering exceptional clarity and dimensional stability, they support wax trees and maintain accuracy during casting.

Fused Silica Sticks

GBC Advanced Materials’ fused silica sticks are indispensable for maintaining clarity and precision in the investment casting process. They are essential in supporting intricate patterns and guaranteeing the integrity of wax trees throughout the casting process.

Fused Silica Mold Supports/Core Rods

We make fused silica supports that are engineered to provide reliable support and stability, aiding in the creation of intricate casting molds. These supports contribute to the precision and quality of cast components, facilitating the production of flawless end products.

Fused Silica Cores

Our fused silica cores are essential for creating hollow structures with intricate geometries in precision casting. They ensure the integrity of cast components by offering exceptional dimensional accuracy and thermal stability. We have grinding capability to ensure tolerances are achieved.

Fused Silica Tubes

Fused silica tubes are designed for versatility and reliability and serve various purposes within investment casting. They are crucial in achieving precise and consistent casting results, from supporting wax trees to facilitating fluid flow.

Our Manufacturing Capabilities

Listed below are the manufacturing capabilities of GBC Advanced Materials in investment casting:

Robust Extrusion Capabilities

We pride ourselves on our robust extrusion process, which enables us to efficiently produce alumina rods, tubes, and fused silica products tailored for investment casting. Our advanced extrusion technology ensures precision and consistency in product dimensions and quality.

Customized Geometries

GBC Advanced Materials offers extruded products in various geometries, including semi-circular, square/rectangular, oval, and custom configurations upon request. This flexibility allows us to provide components tailored to our customers’ casting needs.

Precision Machining

With our in-house machine shop equipped with cutting-edge tools and equipment, we can modify and build tools with precision. This capability enhances our agility and reduces lead times, guaranteeing we respond promptly to customer requirements.

Precise Extrusions

Our extrusion process enables us to manufacture extruded parts with diameters of 0.018-1 inch. As a result, we can cater to various casting applications, accommodating intricate and larger components.

Long Extrusion Lengths

We can produce extruded parts with lengths of up to 36 inches. This capability facilitates the production of extended components required in various casting processes and ensures versatility and efficiency in meeting diverse manufacturing needs.

Agile Response to Customer Needs

Our manufacturing capabilities are complemented by our dedicated sales and engineering team, ready to collaborate with customers on feasibility assessments, design modifications, and cost-reduction initiatives. This proactive approach ensures a seamless production process and enhances customer satisfaction. We have hundreds of extrusion tools in house which help us deliver parts in weeks not months. We provide samples and make prototypes/support low volume and high volume requirements without strict minimum order requirements.

Continuous Investment in Capabilities

We are committed to ongoing investment in our manufacturing capabilities, equipment, and tooling to better serve the evolving needs of the industry. This dedication to innovation and improvement ensures that we remain at the forefront of ceramic solutions for investment casting.

Maximize Your Investment Casting With GBC Advanced Materials!

At GBC Advanced Materials, we provide innovative ceramics solutions tailored to the investment casting industry. With our robust extrusion capabilities, cutting-edge machining technology, and commitment to customer satisfaction, we are ready to meet your casting needs with precision and efficiency.

Contact us today to discover how we can support your casting endeavors!