Thank You for Visiting GBC at the Ceramics Expo

September 15, 2021

Advanced Ceramics in the Energy Industry

November 30, 2021Medical Devices, Electronics, Implants, and More

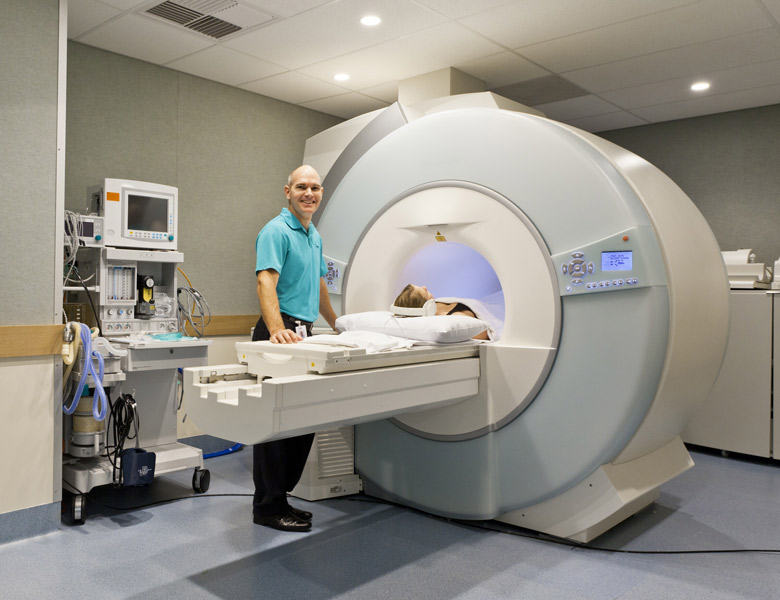

Medical technology is one arena where precision ceramics are both highly valued and expected to increase in use for decades to come. Advanced ceramics serve a wide variety of cutting-edge treatments and technologies.

As demand increases, The Medical Ceramics Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 8.63% from 2020 through 2027.

Precision ceramics fit the bill for use in:

- Ultrasonic sensors, transducers, and therapy devices.

- Infusion pump components and smart pump technology.

- Pump components, valves and seals for liquid transfer applications

- Electro surgery and surgical cameras.

- Imaging devises like Magnetic Resonance Imaging (MRI), Computed Tomography (CT), and Nuclear Medicine (PET).

- Dentistry devices, including descalers, intraoral cameras, and biocompatible materials.

As technology continues to make medical treatments more precise, the need for precision components in these advanced devices will be more important than ever before.

Implantable Electronics and Medical Imaging

Today’s precision ceramics and advanced glass components make applications possible that were either impossible or inconceivable only a few years past. Due to their unique material properties, precision ceramics lead the way in medical technology.

One example is implantable electronic devices like neurostimulators that send pulses to nerves, treating conditions as diverse as sleep apnea, chronic depression, and even obesity. These devices rely heavily on advanced ceramic parts and continually demand smaller and more precise components.

Another advancement is in ceramic resonators, which improve results from targeted MRI imaging. Due to their ability to focus the magnetic field, they are promising alternatives to dedicated RF coils. In nuclear medicine, ceramic scintillators are making the next generation of PET scanners more affordable.

Manufacturing Expertise and Reliability

At GBC Advanced Materials, we have the expertise, production capabilities, and efficient workflow needed to deliver the critical ceramics parts needed by today’s medical industry. Our capabilities include:

- ISO Pressing (including Mechanical Pressing and Cold Isostatic Pressing)

- Green Manufacturing (delivering closer near net dimensions, reducing post-fired/grinding costs and lead times.

- Sintering (applied to a powder compact in order to impart strength, integrity and densification)

- Hard Grinding (precision removal of material resulting in improved surface finishes and precise geometries)

- Extrusion (cross-sectional shapes to create tubes of all shapes and sizes)

- Polishing & Lapping (producing dimensionally accurate specimens to high surface and roughness requirements)

Visit our Capabilities Page to learn more.

Why Choose GBC Advanced Materials?

The future of the advanced ceramics industry is bright, and GBC Advanced Materials has an important role to play. We are chosen by clients in a variety of industries for our low tooling cost, reduced lead times, lower material and machining costs, but most especially for our 30+ years of experience in machining engineered ceramics and specialty materials.

For some of the fastest turnaround times in the industry, state-of-the art materials, and exceptional quality in precision ceramics, email GBC materials at Sales@GBCMaterials.com or visit our Contact Us page today.